Acumen Metering Solutions

Enabling your understanding of well and reservoir performance with intelligent insight

Contact: [email protected]

_819_487_c1_c.png)

Metering Experts

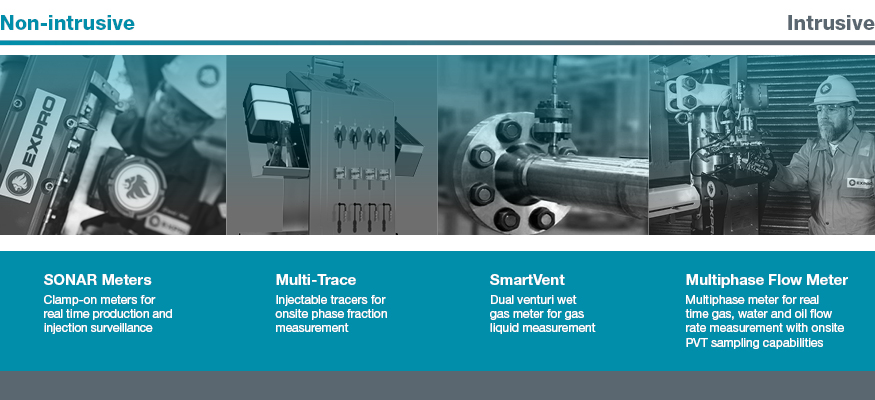

Comprehensive range of metering solutions fully supported by in-house expertise

Case studies

Compact and mobile MPFM Test Package provides data to customer in challenging conditions

Expro provided a compact MPFM testing skid along with Mini Separator for onsite PVT analysis

Get in touch

Contact Acumen Metering Solutions