- A new generation, non-cemented, annular barrier technology was to be evaluated by a deep-water operator, with a means to wirelessly verify the integrity of the barriers also required

- The customer was having difficulty with the cement bond between the casing and carbonate formation and opted to use a combination of new swab packers and more established swell packers to isolate separate zones instead

- Achieving effective cement placement and bonding between the formation and casing can be challenging, especially in deep-water environments and with carbonate formations, where channelling and lost circulation are common problems

- Intelligent well technology is increasingly being applied to enable the reservoir to be managed effectively and the recovery factor to be maximized. Achieving excellent zonal isolation behind casing is critical when planning to produce from multiple zones or deploying intelligent well hardware

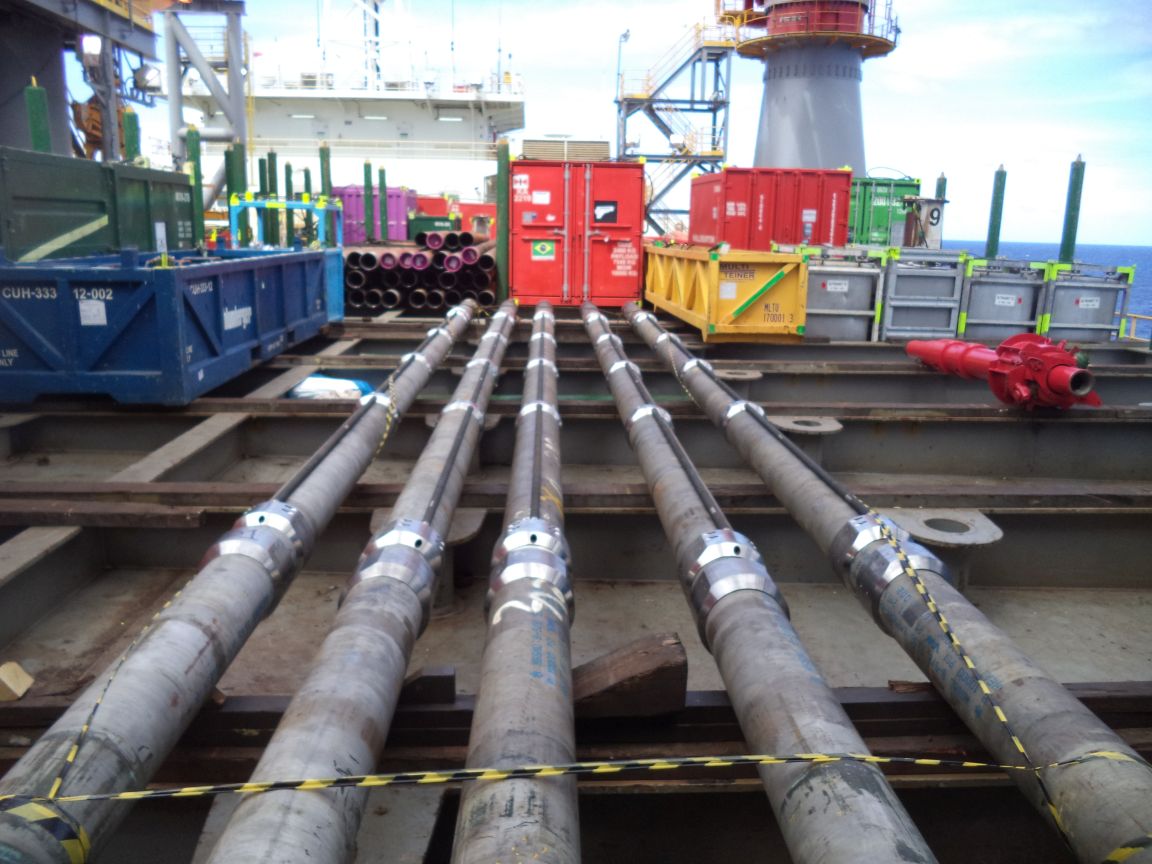

- A total of four CaTS annular barrier monitoring stations, mounted externally on 9 5/8” casing, were successfully deployed inside 12 1/4” open hole or 13 3/8” casing (three discrete reservoir units in a 12 1/4” carbonate open hole section; and a fourth zone, formed between 13 3/8” casing and 9 5/8” liner, the liner hanger, and an expandable barrier

- The third-party barriers comprised a combination of new generation mechanically expandable barriers and more well-established swell packers

- A partnership between the customer and the barrier provider was formed to deliver this novel solution

- The barrier performance was monitored during and after periods of production and injection, with a particular focus on any changes in barrier performance resulting from thermal cycling and acid stimulation

- CaTS data from each of the four zones being monitored was successfully recovered wirelessly over 3 E-line data uploads

- The data proved to be extremely valuable in validating barrier performance under static and dynamic pressure/temperature cycles during flowing and shut-in periods

- CaTS gauges were run with casing (no downhole gauge) therefore no additional rig time required to make up and run – traditional PDG cable, protectors and wellhead wet connectors

- The CaTS system was used to verify and qualify the new third party annular barrier technology so it could be effectively deployed in these environments in place of cemented casing